SPOILER ALERT!

Enhancing Food Safety And Quality Via Batch Pasteurization: Crucial Information For Industry Experts

Article Produced By-Bramsen Shaffer

When it involves making sure the safety and top quality of foodstuff, batch pasteurizers use industry specialists an essential device. By thoroughly managing time and temperature specifications, these devices properly remove dangerous virus and contaminants, securing the honesty of food things. The role of batch pasteurizers exceeds simple sterilization; it encompasses a comprehensive technique to maintaining nutritional value and extending shelf life. As you take into consideration the complex effect of batch pasteurizers on food safety and quality, you'll discover necessary understandings that can boost your sector techniques.

## Relevance of batch Pasteurizers

When it involves making certain food security and top quality, batch pasteurizers play a crucial role. These devices are essential for getting rid of hazardous bacteria and virus from food, protecting against foodborne health problems, and expanding the service life of disposable products. By subjecting food to regulated temperatures, batch pasteurizers effectively ruin dangerous microbes that might otherwise infect the food supply chain. click here for more info preserves the stability and quality of the food being refined.

Along with improving food safety and security, batch pasteurizers contribute in protecting the nutritional worth of food products. The mild heating process utilized by these makers assists maintain vitamins, minerals, and various other vital nutrients in the food, guaranteeing that consumers receive items that aren't just secure but also healthy.

Furthermore, batch pasteurizers add to keeping the flavor, structure, and overall high quality of food items, providing customers with products that fulfill high criteria of taste and freshness.

## Perks for Food Safety And Security

To ensure ideal food security standards, batch pasteurizers use a range of benefits that are indispensable in the food handling sector. These pasteurizers effectively remove dangerous bacteria, virus, and other pollutants that can compromise the safety of food. By subjecting the food to exact time and temperature level controls during the pasteurization procedure, batch pasteurizers aid ruin bacteria that may cause foodborne health problems. visit their website results in a substantial reduction in the risk of pathogens entering the food supply chain, therefore improving consumer safety.

batch pasteurizers also contribute to extending the shelf life of different food products. By removing hazardous bacteria, mold and mildews, and yeasts, these pasteurizers prevent perishing and maintain the freshness of foods for longer durations. This not just enhances food safety but also lessens food waste, ensuring that products continue to be safe for consumption over an extensive duration.

Additionally, batch pasteurizers offer a trustworthy and consistent technique for attaining food safety and security requirements, permitting food processing facilities to satisfy regulatory requirements and deliver top notch, risk-free items to customers. By buying batch pasteurization modern technology, food market experts can enhance food security techniques and build count on with their consumers.

## Enhancing Product Top Quality

With batch pasteurizers, you can not just make certain food safety and security but also enhance the general top quality of your products. By utilizing batch pasteurization approaches, you can achieve much better conservation of tastes, structures, and nutrients in your food products. The mild heat treatment given by batch pasteurizers helps maintain the stability of your components, leading to a higher quality output that keeps its quality and preference for longer periods.

Furthermore, batch pasteurization helps in reducing the microbial load in your products without compromising their sensory qualities. This indicates that you can supply more secure products to customers while ensuring that they fulfill the finest quality criteria.

The precise control over temperature and time specifications offered by batch pasteurizers makes certain that your items are sterilized properly, resulting in enhanced top quality and expanded service life.

## Verdict

Finally, batch pasteurizers are crucial for sector specialists aiming to improve food security and high quality. By successfully eliminating harmful microorganisms and virus, these devices make certain the manufacturing of top quality, risk-free food products for consumers. With precise time and temperature level controls throughout pasteurization, batch pasteurizers play an important function in maintaining the nutritional worth of food and prolonging shelf life. Incorporating batch pasteurizers into food manufacturing processes is key to ensuring customer wellness and well-being.

When it involves making sure the safety and top quality of foodstuff, batch pasteurizers use industry specialists an essential device. By thoroughly managing time and temperature specifications, these devices properly remove dangerous virus and contaminants, securing the honesty of food things. The role of batch pasteurizers exceeds simple sterilization; it encompasses a comprehensive technique to maintaining nutritional value and extending shelf life. As you take into consideration the complex effect of batch pasteurizers on food safety and quality, you'll discover necessary understandings that can boost your sector techniques.

## Relevance of batch Pasteurizers

When it involves making certain food security and top quality, batch pasteurizers play a crucial role. These devices are essential for getting rid of hazardous bacteria and virus from food, protecting against foodborne health problems, and expanding the service life of disposable products. By subjecting food to regulated temperatures, batch pasteurizers effectively ruin dangerous microbes that might otherwise infect the food supply chain. click here for more info preserves the stability and quality of the food being refined.

Along with improving food safety and security, batch pasteurizers contribute in protecting the nutritional worth of food products. The mild heating process utilized by these makers assists maintain vitamins, minerals, and various other vital nutrients in the food, guaranteeing that consumers receive items that aren't just secure but also healthy.

Furthermore, batch pasteurizers add to keeping the flavor, structure, and overall high quality of food items, providing customers with products that fulfill high criteria of taste and freshness.

## Perks for Food Safety And Security

To ensure ideal food security standards, batch pasteurizers use a range of benefits that are indispensable in the food handling sector. These pasteurizers effectively remove dangerous bacteria, virus, and other pollutants that can compromise the safety of food. By subjecting the food to exact time and temperature level controls during the pasteurization procedure, batch pasteurizers aid ruin bacteria that may cause foodborne health problems. visit their website results in a substantial reduction in the risk of pathogens entering the food supply chain, therefore improving consumer safety.

batch pasteurizers also contribute to extending the shelf life of different food products. By removing hazardous bacteria, mold and mildews, and yeasts, these pasteurizers prevent perishing and maintain the freshness of foods for longer durations. This not just enhances food safety but also lessens food waste, ensuring that products continue to be safe for consumption over an extensive duration.

Additionally, batch pasteurizers offer a trustworthy and consistent technique for attaining food safety and security requirements, permitting food processing facilities to satisfy regulatory requirements and deliver top notch, risk-free items to customers. By buying batch pasteurization modern technology, food market experts can enhance food security techniques and build count on with their consumers.

## Enhancing Product Top Quality

With batch pasteurizers, you can not just make certain food safety and security but also enhance the general top quality of your products. By utilizing batch pasteurization approaches, you can achieve much better conservation of tastes, structures, and nutrients in your food products. The mild heat treatment given by batch pasteurizers helps maintain the stability of your components, leading to a higher quality output that keeps its quality and preference for longer periods.

Furthermore, batch pasteurization helps in reducing the microbial load in your products without compromising their sensory qualities. This indicates that you can supply more secure products to customers while ensuring that they fulfill the finest quality criteria.

The precise control over temperature and time specifications offered by batch pasteurizers makes certain that your items are sterilized properly, resulting in enhanced top quality and expanded service life.

## Verdict

Finally, batch pasteurizers are crucial for sector specialists aiming to improve food security and high quality. By successfully eliminating harmful microorganisms and virus, these devices make certain the manufacturing of top quality, risk-free food products for consumers. With precise time and temperature level controls throughout pasteurization, batch pasteurizers play an important function in maintaining the nutritional worth of food and prolonging shelf life. Incorporating batch pasteurizers into food manufacturing processes is key to ensuring customer wellness and well-being.

SPOILER ALERT!

Keen On Picking The Best Tunnel Pasteurizer For Your Service? Discover Key Factors To Take Into Consideration For Optimal Manufacturing Efficiency And Item Quality

Write-Up By-Gallegos Lawrence

When selecting the suitable Tunnel pasteurizer for your company, you face a vital decision that can affect your manufacturing performance substantially. The process includes evaluating numerous variables like size, capacity, temperature control, and maintenance needs. It's not just about the preliminary acquisition; it's likewise about long-term functional prices and assistance. Comprehending the nuances of various Tunnel pasteurizer types and their suitability for your certain demands is extremely important. Your selection will play a crucial duty in guaranteeing the top quality and safety and security of your products while maximizing your manufacturing processes.

## Trick Aspects to Think About

When choosing a passage pasteurizer for your company, it's essential to think about several key aspects that will certainly impact the efficiency and effectiveness of your pasteurization process.

To start with, analyze the dimension and ability needs of your production line. Make sure the Tunnel pasteurizer you pick can manage the volume of items you require to refine to avoid traffic jams or delays in production.

Secondly, think about the home heating and cooling down capabilities of the pasteurizer. The temperature level control accuracy is vital to make sure that your products are sterilized effectively without jeopardizing top quality. Search for a tunnel pasteurizer that uses precise temperature level surveillance and modification functions to satisfy your details pasteurization demands.

One more important aspect to take into consideration is the impact and design of the Tunnel pasteurizer. Ensure the tools fits well within your manufacturing facility and can be quickly integrated into your existing line without significant modifications. Additionally, evaluate the maintenance needs and the accessibility of technological support for the pasteurizer to ensure smooth procedures and marginal downtime.

## Sorts Of Tunnel Pasteurizers

To better comprehend the varied alternatives offered on the market, it is very important to check out the various types of Tunnel pasteurizers matched for different manufacturing requirements and processes.

https://niewmedia.com/en/specials/grandmarquee32787/ is the constant Tunnel pasteurizer, suitable for high-volume production with consistent warmth treatment. If you have differing manufacturing rates, a modular Tunnel pasteurizer might be the most effective fit as it enables adaptability in line configurations.

For smaller sized companies, a compact Tunnel pasteurizer could be the appropriate option, using area effectiveness without compromising on pasteurization top quality. If your items need details therapy zones, an adjustable Tunnel pasteurizer could be one of the most appropriate option, making it possible for customization of heat exposure levels.

Furthermore, you could check here can be categorized based upon home heating approaches such as water immersion, heavy steam injection, or hot air, each offering unique benefits depending upon the product being refined. Recognizing these types will assist you choose the Tunnel pasteurizer that aligns ideal with your organization needs.

## Budgeting and Cost Evaluation

Considering the monetary facets of buying a tunnel pasteurizer is an essential action in your business decision-making procedure. When budgeting for a tunnel pasteurizer, take into account not only the preliminary purchase cost however likewise ongoing expenses such as maintenance, energy usage, and prospective upgrades.

Conduct a detailed expense evaluation to identify the total expense of ownership over the lifespan of the tools. Look for Tunnel pasteurizers that supply an equilibrium between upfront expenses and long-term cost savings through energy efficiency and reduced maintenance demands.

Bear in mind to consider any type of additional expenditures such as installment, training, and potential downtime throughout execution. Contrast quotes from different vendors and take into consideration bargaining for a better offer or discovering financing alternatives to alleviate the monetary problem.

## Verdict

To conclude, choosing the right Tunnel pasteurizer for your service requires cautious consideration of elements such as dimension, capability, heating and cooling capabilities, maintenance demands, and technological support availability. Evaluate various sorts of pasteurizers to locate the very best suitable for your manufacturing requirements and budget constraints. Conduct a comprehensive cost analysis to determine the total ownership cost, consisting of installation and potential downtime costs. With these factors in mind, you can make a notified decision that will benefit your service over time.

When selecting the suitable Tunnel pasteurizer for your company, you face a vital decision that can affect your manufacturing performance substantially. The process includes evaluating numerous variables like size, capacity, temperature control, and maintenance needs. It's not just about the preliminary acquisition; it's likewise about long-term functional prices and assistance. Comprehending the nuances of various Tunnel pasteurizer types and their suitability for your certain demands is extremely important. Your selection will play a crucial duty in guaranteeing the top quality and safety and security of your products while maximizing your manufacturing processes.

## Trick Aspects to Think About

When choosing a passage pasteurizer for your company, it's essential to think about several key aspects that will certainly impact the efficiency and effectiveness of your pasteurization process.

To start with, analyze the dimension and ability needs of your production line. Make sure the Tunnel pasteurizer you pick can manage the volume of items you require to refine to avoid traffic jams or delays in production.

Secondly, think about the home heating and cooling down capabilities of the pasteurizer. The temperature level control accuracy is vital to make sure that your products are sterilized effectively without jeopardizing top quality. Search for a tunnel pasteurizer that uses precise temperature level surveillance and modification functions to satisfy your details pasteurization demands.

One more important aspect to take into consideration is the impact and design of the Tunnel pasteurizer. Ensure the tools fits well within your manufacturing facility and can be quickly integrated into your existing line without significant modifications. Additionally, evaluate the maintenance needs and the accessibility of technological support for the pasteurizer to ensure smooth procedures and marginal downtime.

## Sorts Of Tunnel Pasteurizers

To better comprehend the varied alternatives offered on the market, it is very important to check out the various types of Tunnel pasteurizers matched for different manufacturing requirements and processes.

https://niewmedia.com/en/specials/grandmarquee32787/ is the constant Tunnel pasteurizer, suitable for high-volume production with consistent warmth treatment. If you have differing manufacturing rates, a modular Tunnel pasteurizer might be the most effective fit as it enables adaptability in line configurations.

For smaller sized companies, a compact Tunnel pasteurizer could be the appropriate option, using area effectiveness without compromising on pasteurization top quality. If your items need details therapy zones, an adjustable Tunnel pasteurizer could be one of the most appropriate option, making it possible for customization of heat exposure levels.

Furthermore, you could check here can be categorized based upon home heating approaches such as water immersion, heavy steam injection, or hot air, each offering unique benefits depending upon the product being refined. Recognizing these types will assist you choose the Tunnel pasteurizer that aligns ideal with your organization needs.

## Budgeting and Cost Evaluation

Considering the monetary facets of buying a tunnel pasteurizer is an essential action in your business decision-making procedure. When budgeting for a tunnel pasteurizer, take into account not only the preliminary purchase cost however likewise ongoing expenses such as maintenance, energy usage, and prospective upgrades.

Conduct a detailed expense evaluation to identify the total expense of ownership over the lifespan of the tools. Look for Tunnel pasteurizers that supply an equilibrium between upfront expenses and long-term cost savings through energy efficiency and reduced maintenance demands.

Bear in mind to consider any type of additional expenditures such as installment, training, and potential downtime throughout execution. Contrast quotes from different vendors and take into consideration bargaining for a better offer or discovering financing alternatives to alleviate the monetary problem.

## Verdict

To conclude, choosing the right Tunnel pasteurizer for your service requires cautious consideration of elements such as dimension, capability, heating and cooling capabilities, maintenance demands, and technological support availability. Evaluate various sorts of pasteurizers to locate the very best suitable for your manufacturing requirements and budget constraints. Conduct a comprehensive cost analysis to determine the total ownership cost, consisting of installation and potential downtime costs. With these factors in mind, you can make a notified decision that will benefit your service over time.

SPOILER ALERT!

Comprehending The Benefits Of Batch Pasteurization: An In-Depth Resource For Food Manufacturers

Content By-Preston Rosen

When it involves making certain the safety and top quality of food, batch pasteurizers offer industry specialists a vital tool. By diligently controlling time and temperature level specifications, these devices properly eliminate dangerous pathogens and impurities, guarding the integrity of food items. The duty of batch pasteurizers exceeds plain sterilization; it incorporates an extensive approach to preserving nutritional value and extending service life. As you consider the multifaceted impact of batch pasteurizers on food security and quality, you'll reveal important insights that can boost your market techniques.

## Value of batch Pasteurizers

When it concerns guaranteeing food safety and security and top quality, batch pasteurizers play an important role. These equipments are crucial for getting rid of harmful germs and microorganisms from food products, avoiding foodborne illnesses, and prolonging the service life of disposable things. By subjecting food to regulated temperature levels, batch pasteurizers effectively damage damaging bacteria that could or else contaminate the food supply chain. This process not only safeguards customer health however likewise preserves the integrity and freshness of the food being processed.

Along with improving food security, batch pasteurizers contribute in maintaining the dietary worth of food products. The mild home heating process utilized by these devices helps preserve vitamins, minerals, and other essential nutrients in the food, ensuring that customers get items that aren't just secure yet likewise nutritious.

Furthermore, batch pasteurizers contribute to preserving the taste, texture, and total high quality of food things, supplying consumers with products that fulfill high requirements of taste and quality.

## Conveniences for Food Security

To guarantee optimum food safety requirements, batch pasteurizers offer a series of benefits that are essential in the food processing industry. simply click the next internet site eliminate unsafe germs, microorganisms, and various other impurities that can compromise the safety and security of food. By subjecting the food to precise time and temperature level controls throughout the pasteurization procedure, batch pasteurizers aid destroy microorganisms that may trigger foodborne illnesses. This results in a considerable reduction in the threat of microorganisms entering the food supply chain, thus improving customer safety and security.

batch pasteurizers additionally contribute to extending the service life of various food products. By removing harmful bacteria, molds, and yeasts, these pasteurizers hinder spoilage and preserve the freshness of foods for longer durations. This not only improves food security however likewise reduces food waste, guaranteeing that products continue to be risk-free for usage over an extended duration.

Furthermore, batch pasteurizers provide a trusted and constant technique for attaining food safety and security criteria, permitting food processing centers to satisfy regulative demands and supply high-quality, secure products to consumers. By buying batch pasteurization innovation, food industry specialists can enhance food security practices and build depend on with their clients.

## Enhancing Item High Quality

With batch pasteurizers, you can not just make certain food security however additionally enhance the general quality of your products. By utilizing batch pasteurization approaches, you can attain much better preservation of flavors, appearances, and nutrients in your food products. The gentle heat therapy given by batch pasteurizers helps keep the honesty of your active ingredients, causing a higher quality final product that keeps its quality and taste for longer durations.

Furthermore, batch pasteurization helps in lowering the microbial load in your products without endangering their sensory qualities. This indicates that you can deliver much safer products to consumers while making certain that they meet the best standards.

The exact control over temperature and time criteria provided by batch pasteurizers guarantees that your products are pasteurized properly, bring about improved high quality and expanded shelf life.

## Verdict

To conclude, batch pasteurizers are essential for sector experts wanting to improve food safety and security and top quality. By properly getting https://www.fooddive.com/news/sobering-developments-alcoholic-beverage-companies-branch-out-as-people-dr/546354/ of harmful bacteria and virus, these machines ensure the manufacturing of high-grade, risk-free foodstuff for customers. With exact time and temperature level controls during pasteurization, batch pasteurizers play an essential role in maintaining the dietary value of food and expanding shelf life. Integrating batch pasteurizers into food manufacturing processes is crucial to making certain consumer health and wellness and well-being.

When it involves making certain the safety and top quality of food, batch pasteurizers offer industry specialists a vital tool. By diligently controlling time and temperature level specifications, these devices properly eliminate dangerous pathogens and impurities, guarding the integrity of food items. The duty of batch pasteurizers exceeds plain sterilization; it incorporates an extensive approach to preserving nutritional value and extending service life. As you consider the multifaceted impact of batch pasteurizers on food security and quality, you'll reveal important insights that can boost your market techniques.

## Value of batch Pasteurizers

When it concerns guaranteeing food safety and security and top quality, batch pasteurizers play an important role. These equipments are crucial for getting rid of harmful germs and microorganisms from food products, avoiding foodborne illnesses, and prolonging the service life of disposable things. By subjecting food to regulated temperature levels, batch pasteurizers effectively damage damaging bacteria that could or else contaminate the food supply chain. This process not only safeguards customer health however likewise preserves the integrity and freshness of the food being processed.

Along with improving food security, batch pasteurizers contribute in maintaining the dietary worth of food products. The mild home heating process utilized by these devices helps preserve vitamins, minerals, and other essential nutrients in the food, ensuring that customers get items that aren't just secure yet likewise nutritious.

Furthermore, batch pasteurizers contribute to preserving the taste, texture, and total high quality of food things, supplying consumers with products that fulfill high requirements of taste and quality.

## Conveniences for Food Security

To guarantee optimum food safety requirements, batch pasteurizers offer a series of benefits that are essential in the food processing industry. simply click the next internet site eliminate unsafe germs, microorganisms, and various other impurities that can compromise the safety and security of food. By subjecting the food to precise time and temperature level controls throughout the pasteurization procedure, batch pasteurizers aid destroy microorganisms that may trigger foodborne illnesses. This results in a considerable reduction in the threat of microorganisms entering the food supply chain, thus improving customer safety and security.

batch pasteurizers additionally contribute to extending the service life of various food products. By removing harmful bacteria, molds, and yeasts, these pasteurizers hinder spoilage and preserve the freshness of foods for longer durations. This not only improves food security however likewise reduces food waste, guaranteeing that products continue to be risk-free for usage over an extended duration.

Furthermore, batch pasteurizers provide a trusted and constant technique for attaining food safety and security criteria, permitting food processing centers to satisfy regulative demands and supply high-quality, secure products to consumers. By buying batch pasteurization innovation, food industry specialists can enhance food security practices and build depend on with their clients.

## Enhancing Item High Quality

With batch pasteurizers, you can not just make certain food security however additionally enhance the general quality of your products. By utilizing batch pasteurization approaches, you can attain much better preservation of flavors, appearances, and nutrients in your food products. The gentle heat therapy given by batch pasteurizers helps keep the honesty of your active ingredients, causing a higher quality final product that keeps its quality and taste for longer durations.

Furthermore, batch pasteurization helps in lowering the microbial load in your products without endangering their sensory qualities. This indicates that you can deliver much safer products to consumers while making certain that they meet the best standards.

The exact control over temperature and time criteria provided by batch pasteurizers guarantees that your products are pasteurized properly, bring about improved high quality and expanded shelf life.

## Verdict

To conclude, batch pasteurizers are essential for sector experts wanting to improve food safety and security and top quality. By properly getting https://www.fooddive.com/news/sobering-developments-alcoholic-beverage-companies-branch-out-as-people-dr/546354/ of harmful bacteria and virus, these machines ensure the manufacturing of high-grade, risk-free foodstuff for customers. With exact time and temperature level controls during pasteurization, batch pasteurizers play an essential role in maintaining the dietary value of food and expanding shelf life. Integrating batch pasteurizers into food manufacturing processes is crucial to making certain consumer health and wellness and well-being.

SPOILER ALERT!

Enhancing Performance: Simplifying Your Manufacturing Procedures With Tunnel Pasteurization Systems

Content Author-Andreassen Childers

Tunnel pasteurizers are huge industrial-scale devices that warm and trendy beverages in order to kill microorganisms and expand their service life. Their efficiency depends on accuracy control.

Several drink companies have retrofitted their existing Tunnel pasteurizers with new environment-friendly modern technologies to attain substantial ecological benefits. These include decreased energy intake, lower water use and lowered greenhouse gas exhausts.

When you run a brewery, your goal isn't just to get rid of harmful virus, yet also to use uniformity in your products. A well-executed pasteurization process not only prolongs beer's life span, however it makes certain that every bottle of your beer will certainly taste the very same, from your first set to your last. This is especially crucial for craft breweries seeking to draw in health-conscious consumers that want the fizzy goodness of carbonated drinks.

Tunnel pasteurizers work by bringing containers and cans as much as their preferred temperature in stages, holding them there for long enough to kill off the microbes that cause wasting. They then bring them down once again in incremental steps up until they reach area temperature level, preserving preference accounts. By doing this, they not just prevent microorganisms from multiplying in the product, yet they likewise lower power consumption by removing warmth loss. These are the kinds of performance gains that can build up promptly.

As more emphasis is put on environment-friendly production techniques, beverage manufacturers are trying to find ways to decrease their waste production. Tunnel pasteurizers do a terrific work of this, particularly when they are developed and developed by experienced experts.

Tunnel pasteurizers utilize a collection of sprays to warm the bottles or containers as they move with the maker. This eliminates the need for a large steam storage tank that consumes power and drainages. On top of that, Tunnel pasteurizers make use of a water cost savings system to recycle the hot water utilized in the heating procedure, which minimizes water and sewage system use.

Recommended Internet site of Tunnel pasteurization is its compatibility with carbonated drinks, which is a big selling point for craft makers who wish to extend their items' service life and make sure uniformity between sets. Unlike flash pasteurizers, which sometimes deal with high degrees of carbonation, Tunnel devices can handle these effervescent concoctions without breaking a sweat (or a container).

When your beverages are properly treated in Tunnel pasteurizers, they're safeguarded from hazardous bacteria while preserving their flavor profiles. This implies your brews, sodas, acid maintains (like fruits or acids), and wellness shots can extend their service life without losing their signature preference.

In order to achieve this, tunnels feature accurate temperature level control and also distribution throughout their numerous stages. In addition, conveyor belt rates assist make sure equal treatment times for every bottle getting in the equipment. All this helps you ensure quality outcomes whenever.

Finally, tunnels are compatible with carbonated beverages, an expanding pattern among health-conscious customers looking for fizzy options to sugary sodas. Unlike flash pasteurizers, which can deal with high-carbonation degrees, Tunnel machines are developed to manage them.

Additionally, https://www.goodfood.com.au/eat-out/news/victorias-artisan-dairy-industry-is-producing-some-of-the-nations-finest-butter-and-milk-20180713-h12n4j with power recovery systems reduces water usage also. By using the retrieved water for air conditioning, you'll dramatically cut your power intake and greenhouse gas discharges.

Tunnel pasteurizers are energy-intensive machines, but you can decrease your energy consumption by retrofitting them with innovative environment-friendly technology. This includes solar-powered burner that can run on renewable energy sources, reducing dependence on fossil fuels and your carbon footprint.

An additional great feature of Tunnel pasteurizers is that they are compatible with carbonated beverages, a prominent fad amongst today's health-conscious customers. Unlike flash pasteurizers, which often have problem with high-carbonation degrees, Tunnel units can take care of these fizzy mixtures effortlessly.

zPasteurAIzer can monitor the effectiveness of your current Tunnel pasteurizer by approximating the built up product top quality (PU) value for each batch. This enables you to figure out if your existing temperature control system is providing enough heat therapy in addition to determining any type of bent spray heads. You can then readjust the maker setups based on your favored PU values, increasing manufacturing effectiveness while decreasing power consumption. This is a terrific method to cut down your water usage as well, straightening your service with consumer demand for ecologically liable items.

Tunnel pasteurizers are huge industrial-scale devices that warm and trendy beverages in order to kill microorganisms and expand their service life. Their efficiency depends on accuracy control.

Several drink companies have retrofitted their existing Tunnel pasteurizers with new environment-friendly modern technologies to attain substantial ecological benefits. These include decreased energy intake, lower water use and lowered greenhouse gas exhausts.

1. Boosted Performance

When you run a brewery, your goal isn't just to get rid of harmful virus, yet also to use uniformity in your products. A well-executed pasteurization process not only prolongs beer's life span, however it makes certain that every bottle of your beer will certainly taste the very same, from your first set to your last. This is especially crucial for craft breweries seeking to draw in health-conscious consumers that want the fizzy goodness of carbonated drinks.

Tunnel pasteurizers work by bringing containers and cans as much as their preferred temperature in stages, holding them there for long enough to kill off the microbes that cause wasting. They then bring them down once again in incremental steps up until they reach area temperature level, preserving preference accounts. By doing this, they not just prevent microorganisms from multiplying in the product, yet they likewise lower power consumption by removing warmth loss. These are the kinds of performance gains that can build up promptly.

2. Lowered Waste

As more emphasis is put on environment-friendly production techniques, beverage manufacturers are trying to find ways to decrease their waste production. Tunnel pasteurizers do a terrific work of this, particularly when they are developed and developed by experienced experts.

Tunnel pasteurizers utilize a collection of sprays to warm the bottles or containers as they move with the maker. This eliminates the need for a large steam storage tank that consumes power and drainages. On top of that, Tunnel pasteurizers make use of a water cost savings system to recycle the hot water utilized in the heating procedure, which minimizes water and sewage system use.

Recommended Internet site of Tunnel pasteurization is its compatibility with carbonated drinks, which is a big selling point for craft makers who wish to extend their items' service life and make sure uniformity between sets. Unlike flash pasteurizers, which sometimes deal with high degrees of carbonation, Tunnel devices can handle these effervescent concoctions without breaking a sweat (or a container).

3. Much Better Item High Quality

When your beverages are properly treated in Tunnel pasteurizers, they're safeguarded from hazardous bacteria while preserving their flavor profiles. This implies your brews, sodas, acid maintains (like fruits or acids), and wellness shots can extend their service life without losing their signature preference.

In order to achieve this, tunnels feature accurate temperature level control and also distribution throughout their numerous stages. In addition, conveyor belt rates assist make sure equal treatment times for every bottle getting in the equipment. All this helps you ensure quality outcomes whenever.

Finally, tunnels are compatible with carbonated beverages, an expanding pattern among health-conscious customers looking for fizzy options to sugary sodas. Unlike flash pasteurizers, which can deal with high-carbonation degrees, Tunnel machines are developed to manage them.

Additionally, https://www.goodfood.com.au/eat-out/news/victorias-artisan-dairy-industry-is-producing-some-of-the-nations-finest-butter-and-milk-20180713-h12n4j with power recovery systems reduces water usage also. By using the retrieved water for air conditioning, you'll dramatically cut your power intake and greenhouse gas discharges.

4. Minimized Power Usage

Tunnel pasteurizers are energy-intensive machines, but you can decrease your energy consumption by retrofitting them with innovative environment-friendly technology. This includes solar-powered burner that can run on renewable energy sources, reducing dependence on fossil fuels and your carbon footprint.

An additional great feature of Tunnel pasteurizers is that they are compatible with carbonated beverages, a prominent fad amongst today's health-conscious customers. Unlike flash pasteurizers, which often have problem with high-carbonation degrees, Tunnel units can take care of these fizzy mixtures effortlessly.

zPasteurAIzer can monitor the effectiveness of your current Tunnel pasteurizer by approximating the built up product top quality (PU) value for each batch. This enables you to figure out if your existing temperature control system is providing enough heat therapy in addition to determining any type of bent spray heads. You can then readjust the maker setups based on your favored PU values, increasing manufacturing effectiveness while decreasing power consumption. This is a terrific method to cut down your water usage as well, straightening your service with consumer demand for ecologically liable items.

SPOILER ALERT!

Increasing Performance: Maximizing Your Production Line With Tunnel Pasteurizers

Web Content Composed By-Didriksen Cohen

Tunnel pasteurizers are huge industrial-scale machines that warmth and amazing drinks in order to eliminate microorganisms and extend their shelf life. Their effectiveness depends on accuracy control.

A number of drink firms have actually retrofitted their existing Tunnel pasteurizers with brand-new green innovations to attain significant environmental advantages. These consist of decreased power intake, reduced water usage and decreased greenhouse gas discharges.

When you run a brewery, your goal isn't simply to get rid of damaging virus, but also to supply uniformity in your items. A well-executed pasteurization process not just lengthens beer's shelf life, however it guarantees that every bottle of your beer will taste the exact same, from your initial batch to your last. This is specifically crucial for craft breweries wanting to bring in health-conscious consumers who want the carbonated benefits of carbonated drinks.

Tunnel pasteurizers function by bringing containers and containers approximately their wanted temperature in phases, holding them there for long enough to exterminate the microbes that trigger perishing. They then bring them down once again in incremental actions until they reach room temperature, preserving taste profiles. By doing this, they not just stop bacteria from multiplying in the item, yet they likewise reduce energy intake by removing warm loss. These are the type of efficiency gains that can accumulate rapidly.

As more emphasis is placed on environment-friendly manufacturing methods, drink manufacturers are trying to find methods to lower their waste manufacturing. Tunnel pasteurizers do a great task of this, specifically when they are designed and developed by seasoned professionals.

Tunnel pasteurizers utilize a series of sprays to heat the bottles or cans as they relocate via the maker. This removes the requirement for a big steam storage tank that consumes energy and drainages. On top of that, Tunnel pasteurizers utilize a water cost savings system to reuse the warm water made use of in the home heating process, which reduces water and sewage system use.

An additional advantage of Tunnel pasteurization is its compatibility with carbonated drinks, which is a huge marketing factor for craft brewers that wish to extend their products' shelf life and guarantee consistency in between sets. Unlike flash pasteurizers, which occasionally deal with high degrees of carbonation, Tunnel devices can take care of these bubbly concoctions without breaking a sweat (or a bottle).

When your drinks are effectively treated in Tunnel pasteurizers, they're secured from hazardous microorganisms while maintaining their taste profiles. This indicates your mixtures, soft drinks, acid protects (like fruits or acids), and health shots can prolong their shelf life without losing their trademark taste.

In https://www.foodsafetynews.com/2020/04/data-shows-connection-between-unpasteurized-milk-and-infections/ to attain this, tunnels feature specific temperature level control and even distribution throughout their multiple phases. Additionally, conveyor belt rates aid ensure equivalent therapy times for each bottle entering the machine. All this aids you ensure quality results every time.

Lastly, tunnels are compatible with carbonated beverages, an expanding trend amongst health-conscious customers seeking carbonated choices to sweet sodas. Unlike flash pasteurizers, which can struggle with high-carbonation levels, Tunnel machines are developed to handle them.

Additionally, retrofitting passages with energy recovery systems minimizes water use as well. By utilizing webpage recovered water for air conditioning, you'll considerably cut your energy consumption and greenhouse gas exhausts.

Tunnel pasteurizers are energy-intensive devices, however you can reduce your power consumption by retrofitting them with cutting-edge environmentally friendly innovation. This consists of solar-powered burner that can work on renewable resource resources, reducing reliance on nonrenewable fuel sources and your carbon footprint.

Another excellent attribute of Tunnel pasteurizers is that they are compatible with carbonated beverages, a popular trend among today's health-conscious consumers. Unlike flash pasteurizers, which sometimes have problem with high-carbonation levels, Tunnel units can manage these fizzy concoctions effortlessly.

zPasteurAIzer can keep track of the effectiveness of your existing Tunnel pasteurizer by approximating the accumulated product quality (PU) worth for each and every set. This allows you to establish if your current temperature control system is providing enough warm treatment along with recognizing any bent spray heads. You can after that change the equipment setups based on your favored PU worths, enhancing manufacturing performance while decreasing energy consumption. This is a great method to reduce your water intake also, aligning your company with consumer demand for eco accountable products.

Tunnel pasteurizers are huge industrial-scale machines that warmth and amazing drinks in order to eliminate microorganisms and extend their shelf life. Their effectiveness depends on accuracy control.

A number of drink firms have actually retrofitted their existing Tunnel pasteurizers with brand-new green innovations to attain significant environmental advantages. These consist of decreased power intake, reduced water usage and decreased greenhouse gas discharges.

1. Enhanced Performance

When you run a brewery, your goal isn't simply to get rid of damaging virus, but also to supply uniformity in your items. A well-executed pasteurization process not just lengthens beer's shelf life, however it guarantees that every bottle of your beer will taste the exact same, from your initial batch to your last. This is specifically crucial for craft breweries wanting to bring in health-conscious consumers who want the carbonated benefits of carbonated drinks.

Tunnel pasteurizers function by bringing containers and containers approximately their wanted temperature in phases, holding them there for long enough to exterminate the microbes that trigger perishing. They then bring them down once again in incremental actions until they reach room temperature, preserving taste profiles. By doing this, they not just stop bacteria from multiplying in the item, yet they likewise reduce energy intake by removing warm loss. These are the type of efficiency gains that can accumulate rapidly.

2. Reduced Waste

As more emphasis is placed on environment-friendly manufacturing methods, drink manufacturers are trying to find methods to lower their waste manufacturing. Tunnel pasteurizers do a great task of this, specifically when they are designed and developed by seasoned professionals.

Tunnel pasteurizers utilize a series of sprays to heat the bottles or cans as they relocate via the maker. This removes the requirement for a big steam storage tank that consumes energy and drainages. On top of that, Tunnel pasteurizers utilize a water cost savings system to reuse the warm water made use of in the home heating process, which reduces water and sewage system use.

An additional advantage of Tunnel pasteurization is its compatibility with carbonated drinks, which is a huge marketing factor for craft brewers that wish to extend their products' shelf life and guarantee consistency in between sets. Unlike flash pasteurizers, which occasionally deal with high degrees of carbonation, Tunnel devices can take care of these bubbly concoctions without breaking a sweat (or a bottle).

3. Better Product Quality

When your drinks are effectively treated in Tunnel pasteurizers, they're secured from hazardous microorganisms while maintaining their taste profiles. This indicates your mixtures, soft drinks, acid protects (like fruits or acids), and health shots can prolong their shelf life without losing their trademark taste.

In https://www.foodsafetynews.com/2020/04/data-shows-connection-between-unpasteurized-milk-and-infections/ to attain this, tunnels feature specific temperature level control and even distribution throughout their multiple phases. Additionally, conveyor belt rates aid ensure equivalent therapy times for each bottle entering the machine. All this aids you ensure quality results every time.

Lastly, tunnels are compatible with carbonated beverages, an expanding trend amongst health-conscious customers seeking carbonated choices to sweet sodas. Unlike flash pasteurizers, which can struggle with high-carbonation levels, Tunnel machines are developed to handle them.

Additionally, retrofitting passages with energy recovery systems minimizes water use as well. By utilizing webpage recovered water for air conditioning, you'll considerably cut your energy consumption and greenhouse gas exhausts.

4. Reduced Energy Intake

Tunnel pasteurizers are energy-intensive devices, however you can reduce your power consumption by retrofitting them with cutting-edge environmentally friendly innovation. This consists of solar-powered burner that can work on renewable resource resources, reducing reliance on nonrenewable fuel sources and your carbon footprint.

Another excellent attribute of Tunnel pasteurizers is that they are compatible with carbonated beverages, a popular trend among today's health-conscious consumers. Unlike flash pasteurizers, which sometimes have problem with high-carbonation levels, Tunnel units can manage these fizzy concoctions effortlessly.

zPasteurAIzer can keep track of the effectiveness of your existing Tunnel pasteurizer by approximating the accumulated product quality (PU) worth for each and every set. This allows you to establish if your current temperature control system is providing enough warm treatment along with recognizing any bent spray heads. You can after that change the equipment setups based on your favored PU worths, enhancing manufacturing performance while decreasing energy consumption. This is a great method to reduce your water intake also, aligning your company with consumer demand for eco accountable products.

SPOILER ALERT!

Boosting Performance: Enhancing Your Manufacturing Refine Utilizing Tunnel Pasteurization Tools

Write-Up By-Abel Melton

Tunnel pasteurizers are huge industrial-scale equipments that warm and amazing drinks in order to eliminate microbes and extend their shelf life. Their effectiveness depends on precision control.

A number of drink companies have actually retrofitted their existing Tunnel pasteurizers with brand-new environmentally friendly modern technologies to accomplish considerable ecological benefits. These include decreased power usage, lower water usage and lowered greenhouse gas emissions.

When you run a brewery, your goal isn't simply to get rid of damaging virus, yet additionally to provide uniformity in your products. A well-executed pasteurization process not just prolongs beer's life span, yet it ensures that every container of your beer will certainly taste the same, from your initial set to your last. This is particularly vital for craft breweries seeking to draw in health-conscious customers who want the carbonated goodness of carbonated drinks.

Tunnel pasteurizers work by bringing containers and canisters up to their preferred temperature level in phases, holding them there for long enough to exterminate the microbes that trigger spoilage. They after that bring them down again in incremental actions till they get to space temperature, preserving preference accounts. By doing this, they not just prevent bacteria from increasing in the product, yet they also reduce energy intake by removing heat loss. These are the type of effectiveness gains that can add up swiftly.

As even more emphasis is placed on green production practices, drink producers are seeking ways to lower their waste production. Tunnel pasteurizers do a wonderful job of this, particularly when they are created and built by skilled experts.

Tunnel pasteurizers use a series of sprays to heat up the bottles or canisters as they move through the equipment. This removes the need for a huge steam container that consumes power and drainages. Additionally, Tunnel pasteurizers use a water cost savings system to reuse the hot water utilized in the home heating process, which decreases water and sewage system use.

An additional advantage of Tunnel pasteurization is its compatibility with carbonated drinks, which is a big selling factor for craft brewers who intend to expand their items' service life and make sure consistency between sets. Unlike flash pasteurizers, which sometimes deal with high levels of carbonation, Tunnel systems can handle these bubbly concoctions without breaking a sweat (or a container).

When your drinks are correctly dealt with in Tunnel pasteurizers, they're protected from unsafe bacteria while preserving their taste accounts. This suggests your mixtures, soft drinks, acid protects (like fruits or acids), and health shots can expand their shelf life without shedding their trademark taste.

In order to attain this, tunnels feature accurate temperature control and also distribution throughout their multiple phases. In addition, conveyor belt speeds aid make certain equal therapy times for every container entering the equipment. All this assists you guarantee top quality outcomes whenever.

Finally, tunnels are compatible with carbonated beverages, an expanding pattern amongst health-conscious customers searching for fizzy choices to sweet sodas. Unlike flash pasteurizers, which can deal with high-carbonation degrees, Tunnel equipments are created to handle them.

Moreover, retrofitting tunnels with energy recovery systems minimizes water use also. By using the retrieved water for air conditioning, you'll substantially cut your power consumption and greenhouse gas emissions.

Tunnel pasteurizers are energy-intensive equipments, yet you can lower your power intake by retrofitting them with innovative environment-friendly innovation. This includes solar-powered heating elements that can run on renewable resource resources, decreasing dependence on nonrenewable fuel sources and your carbon impact.

An additional excellent feature of Tunnel pasteurizers is that they work with carbonated beverages, a prominent fad amongst today's health-conscious consumers. Unlike flash pasteurizers, which often have problem with high-carbonation levels, Tunnel devices can deal with these fizzy mixtures easily.

zPasteurAIzer can check the performance of your existing Tunnel pasteurizer by estimating the built up item top quality (PU) worth for each set. This allows you to figure out if your current temperature level control system is supplying sufficient warm therapy along with determining any kind of curved spray heads. just click the following web page can then change the maker setups based upon your preferred PU values, raising manufacturing effectiveness while reducing power intake. This is a great way to cut down your water intake too, aligning your company with consumer demand for environmentally responsible products.

Tunnel pasteurizers are huge industrial-scale equipments that warm and amazing drinks in order to eliminate microbes and extend their shelf life. Their effectiveness depends on precision control.

A number of drink companies have actually retrofitted their existing Tunnel pasteurizers with brand-new environmentally friendly modern technologies to accomplish considerable ecological benefits. These include decreased power usage, lower water usage and lowered greenhouse gas emissions.

1. Increased Efficiency

When you run a brewery, your goal isn't simply to get rid of damaging virus, yet additionally to provide uniformity in your products. A well-executed pasteurization process not just prolongs beer's life span, yet it ensures that every container of your beer will certainly taste the same, from your initial set to your last. This is particularly vital for craft breweries seeking to draw in health-conscious customers who want the carbonated goodness of carbonated drinks.

Tunnel pasteurizers work by bringing containers and canisters up to their preferred temperature level in phases, holding them there for long enough to exterminate the microbes that trigger spoilage. They after that bring them down again in incremental actions till they get to space temperature, preserving preference accounts. By doing this, they not just prevent bacteria from increasing in the product, yet they also reduce energy intake by removing heat loss. These are the type of effectiveness gains that can add up swiftly.

2. Minimized Waste

As even more emphasis is placed on green production practices, drink producers are seeking ways to lower their waste production. Tunnel pasteurizers do a wonderful job of this, particularly when they are created and built by skilled experts.

Tunnel pasteurizers use a series of sprays to heat up the bottles or canisters as they move through the equipment. This removes the need for a huge steam container that consumes power and drainages. Additionally, Tunnel pasteurizers use a water cost savings system to reuse the hot water utilized in the home heating process, which decreases water and sewage system use.

An additional advantage of Tunnel pasteurization is its compatibility with carbonated drinks, which is a big selling factor for craft brewers who intend to expand their items' service life and make sure consistency between sets. Unlike flash pasteurizers, which sometimes deal with high levels of carbonation, Tunnel systems can handle these bubbly concoctions without breaking a sweat (or a container).

3. Much Better Item Top Quality

When your drinks are correctly dealt with in Tunnel pasteurizers, they're protected from unsafe bacteria while preserving their taste accounts. This suggests your mixtures, soft drinks, acid protects (like fruits or acids), and health shots can expand their shelf life without shedding their trademark taste.

In order to attain this, tunnels feature accurate temperature control and also distribution throughout their multiple phases. In addition, conveyor belt speeds aid make certain equal therapy times for every container entering the equipment. All this assists you guarantee top quality outcomes whenever.

Finally, tunnels are compatible with carbonated beverages, an expanding pattern amongst health-conscious customers searching for fizzy choices to sweet sodas. Unlike flash pasteurizers, which can deal with high-carbonation degrees, Tunnel equipments are created to handle them.

Moreover, retrofitting tunnels with energy recovery systems minimizes water use also. By using the retrieved water for air conditioning, you'll substantially cut your power consumption and greenhouse gas emissions.

4. Lowered Energy Intake

Tunnel pasteurizers are energy-intensive equipments, yet you can lower your power intake by retrofitting them with innovative environment-friendly innovation. This includes solar-powered heating elements that can run on renewable resource resources, decreasing dependence on nonrenewable fuel sources and your carbon impact.

An additional excellent feature of Tunnel pasteurizers is that they work with carbonated beverages, a prominent fad amongst today's health-conscious consumers. Unlike flash pasteurizers, which often have problem with high-carbonation levels, Tunnel devices can deal with these fizzy mixtures easily.

zPasteurAIzer can check the performance of your existing Tunnel pasteurizer by estimating the built up item top quality (PU) worth for each set. This allows you to figure out if your current temperature level control system is supplying sufficient warm therapy along with determining any kind of curved spray heads. just click the following web page can then change the maker setups based upon your preferred PU values, raising manufacturing effectiveness while reducing power intake. This is a great way to cut down your water intake too, aligning your company with consumer demand for environmentally responsible products.

SPOILER ALERT!

Boosting Productivity: Enhancing Your Manufacturing Refine Making Use Of Tunnel Pasteurization Tools

Author-Lynch Childers

Tunnel pasteurizers are big industrial-scale makers that heat and amazing beverages in order to eliminate microorganisms and expand their shelf life. Their efficiency depends on precision control.

A number of beverage firms have retrofitted their existing Tunnel pasteurizers with new environmentally friendly innovations to achieve considerable ecological benefits. These include lowered energy consumption, reduced water usage and reduced greenhouse gas discharges.

When you run a brewery, your goal isn't just to eliminate damaging virus, yet additionally to offer uniformity in your products. over at this website -executed pasteurization process not only prolongs beer's life span, but it makes sure that every container of your beer will certainly taste the very same, from your very first batch to your last. This is especially essential for craft breweries looking to draw in health-conscious customers that desire the fizzy goodness of soft drinks.

Tunnel pasteurizers function by bringing containers and canisters as much as their wanted temperature in stages, holding them there for enough time to exterminate the microbes that cause spoilage. They then bring them down again in incremental actions till they reach area temperature, maintaining taste accounts. By doing this, they not just avoid germs from increasing in the item, however they also reduce energy consumption by eliminating heat loss. These are the sort of efficiency gains that can accumulate quickly.

As more emphasis is positioned on eco-friendly production practices, beverage manufacturers are seeking ways to minimize their waste manufacturing. Tunnel pasteurizers do a great work of this, specifically when they are created and built by experienced experts.

Tunnel pasteurizers make use of a collection of sprays to heat the bottles or cans as they move through the equipment. This removes the need for a large heavy steam container that takes in energy and wastes water. Furthermore, Tunnel pasteurizers utilize a water financial savings system to recycle the warm water made use of in the home heating process, which reduces water and sewer usage.

An additional benefit of Tunnel pasteurization is its compatibility with carbonated drinks, which is a big marketing point for craft brewers that want to prolong their items' life span and guarantee uniformity in between sets. Unlike flash pasteurizers, which often battle with high degrees of carbonation, Tunnel systems can deal with these effervescent mixtures without breaking a sweat (or a container).

When your drinks are correctly dealt with in Tunnel pasteurizers, they're safeguarded from unsafe microorganisms while protecting their taste accounts. This suggests your mixtures, sodas, acid protects (like fruits or acids), and health shots can extend their shelf life without losing their signature preference.

In order to accomplish this, passages feature precise temperature level control and even circulation throughout their several stages. Furthermore, conveyor belt rates assist guarantee equivalent treatment times for each bottle getting in the equipment. https://www.foodsafetynews.com/2021/06/texas-health-department-makes-selling-raw-milk-much-easier/ aids you assure top quality results each time.

Ultimately, passages work with carbonated beverages, an expanding fad among health-conscious customers trying to find carbonated alternatives to sugary soft drinks. Unlike flash pasteurizers, which can have problem with high-carbonation levels, Tunnel makers are made to handle them.

Moreover, retrofitting tunnels with energy recuperation systems decreases water usage also. By using the retrieved water for air conditioning, you'll dramatically cut your power consumption and greenhouse gas exhausts.

Tunnel pasteurizers are energy-intensive makers, but you can lower your energy consumption by retrofitting them with advanced green modern technology. This consists of solar-powered heating elements that can operate on renewable resource sources, reducing reliance on nonrenewable fuel sources and your carbon impact.

An additional fantastic feature of Tunnel pasteurizers is that they are compatible with carbonated beverages, a prominent pattern amongst today's health-conscious consumers. Unlike flash pasteurizers, which occasionally fight with high-carbonation degrees, Tunnel units can handle these fizzy concoctions with ease.

zPasteurAIzer can monitor the effectiveness of your existing Tunnel pasteurizer by estimating the built up product high quality (PU) value for each and every batch. This allows you to identify if your current temperature level control system is providing enough warmth therapy as well as identifying any kind of curved spray heads. You can after that adjust the device settings based on your favored PU worths, raising production efficiency while reducing energy consumption. This is a terrific method to reduce your water intake too, aligning your business with consumer demand for ecologically accountable items.

Tunnel pasteurizers are big industrial-scale makers that heat and amazing beverages in order to eliminate microorganisms and expand their shelf life. Their efficiency depends on precision control.

A number of beverage firms have retrofitted their existing Tunnel pasteurizers with new environmentally friendly innovations to achieve considerable ecological benefits. These include lowered energy consumption, reduced water usage and reduced greenhouse gas discharges.

1. Enhanced Performance

When you run a brewery, your goal isn't just to eliminate damaging virus, yet additionally to offer uniformity in your products. over at this website -executed pasteurization process not only prolongs beer's life span, but it makes sure that every container of your beer will certainly taste the very same, from your very first batch to your last. This is especially essential for craft breweries looking to draw in health-conscious customers that desire the fizzy goodness of soft drinks.

Tunnel pasteurizers function by bringing containers and canisters as much as their wanted temperature in stages, holding them there for enough time to exterminate the microbes that cause spoilage. They then bring them down again in incremental actions till they reach area temperature, maintaining taste accounts. By doing this, they not just avoid germs from increasing in the item, however they also reduce energy consumption by eliminating heat loss. These are the sort of efficiency gains that can accumulate quickly.

2. Lowered Waste

As more emphasis is positioned on eco-friendly production practices, beverage manufacturers are seeking ways to minimize their waste manufacturing. Tunnel pasteurizers do a great work of this, specifically when they are created and built by experienced experts.

Tunnel pasteurizers make use of a collection of sprays to heat the bottles or cans as they move through the equipment. This removes the need for a large heavy steam container that takes in energy and wastes water. Furthermore, Tunnel pasteurizers utilize a water financial savings system to recycle the warm water made use of in the home heating process, which reduces water and sewer usage.

An additional benefit of Tunnel pasteurization is its compatibility with carbonated drinks, which is a big marketing point for craft brewers that want to prolong their items' life span and guarantee uniformity in between sets. Unlike flash pasteurizers, which often battle with high degrees of carbonation, Tunnel systems can deal with these effervescent mixtures without breaking a sweat (or a container).

3. Much Better Product Quality

When your drinks are correctly dealt with in Tunnel pasteurizers, they're safeguarded from unsafe microorganisms while protecting their taste accounts. This suggests your mixtures, sodas, acid protects (like fruits or acids), and health shots can extend their shelf life without losing their signature preference.

In order to accomplish this, passages feature precise temperature level control and even circulation throughout their several stages. Furthermore, conveyor belt rates assist guarantee equivalent treatment times for each bottle getting in the equipment. https://www.foodsafetynews.com/2021/06/texas-health-department-makes-selling-raw-milk-much-easier/ aids you assure top quality results each time.

Ultimately, passages work with carbonated beverages, an expanding fad among health-conscious customers trying to find carbonated alternatives to sugary soft drinks. Unlike flash pasteurizers, which can have problem with high-carbonation levels, Tunnel makers are made to handle them.

Moreover, retrofitting tunnels with energy recuperation systems decreases water usage also. By using the retrieved water for air conditioning, you'll dramatically cut your power consumption and greenhouse gas exhausts.

4. Lowered Power Consumption

Tunnel pasteurizers are energy-intensive makers, but you can lower your energy consumption by retrofitting them with advanced green modern technology. This consists of solar-powered heating elements that can operate on renewable resource sources, reducing reliance on nonrenewable fuel sources and your carbon impact.

An additional fantastic feature of Tunnel pasteurizers is that they are compatible with carbonated beverages, a prominent pattern amongst today's health-conscious consumers. Unlike flash pasteurizers, which occasionally fight with high-carbonation degrees, Tunnel units can handle these fizzy concoctions with ease.

"Elevating Co-Packing Partnerships: The Features and Benefits of Investing in New Tunnel Pasteurizers or Batch Pasteurizers"

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) December 26, 2023

Article Release by PRO Engineering / Manufacturing Inc.

Click for article: https://t.co/efrL1fLtBp

PRO Engineering / Manufacturing Inc.

414-362-1500

zPasteurAIzer can monitor the effectiveness of your existing Tunnel pasteurizer by estimating the built up product high quality (PU) value for each and every batch. This allows you to identify if your current temperature level control system is providing enough warmth therapy as well as identifying any kind of curved spray heads. You can after that adjust the device settings based on your favored PU worths, raising production efficiency while reducing energy consumption. This is a terrific method to reduce your water intake too, aligning your business with consumer demand for ecologically accountable items.

SPOILER ALERT!

Securing Taste And Safety: The Value Of Tunnel Pasteurizers In Drink Manufacturing

Post Composed By-West Morrow

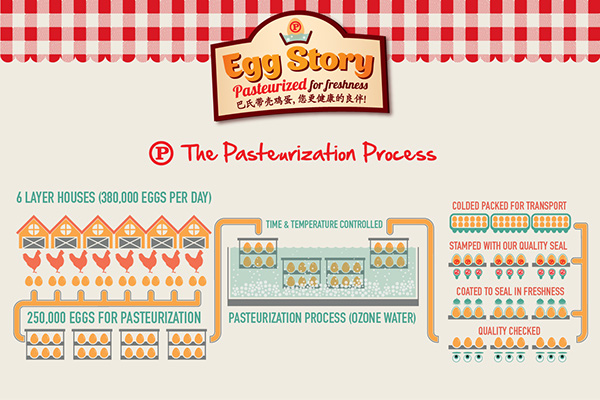

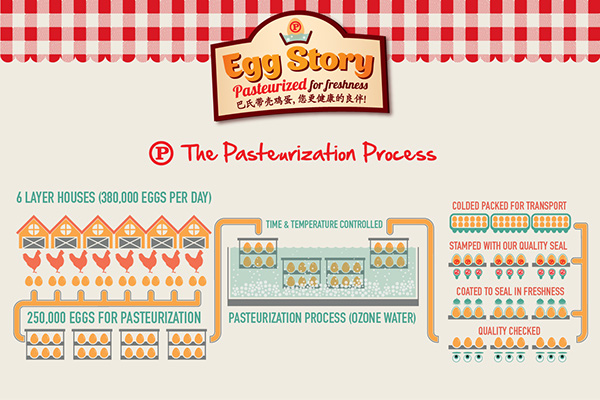

Tunnel pasteurizers are essential for eliminating wasting microbes and controlling pathogenic germs in drinks like beer, milk, juice and soft drinks. They warm and after that cool down the product to eliminate these germs.

They additionally save power, water and lower co2 exhausts straightening production with sustainability targets. Selecting a passage pasteurization system that's crafted by skilled specialists like PRO makes sure accuracy in the timing and temperature levels used in each phase.

The control of bacteria in food and beverages is important to stop perishing, gastrointestinal disorder, and other unfavorable influence on the end product. Microbial contaminations can be brought on by pathogenic (i.e., disease-causing) microorganisms or perishing fungi. just click the up coming document for regulating microbial contamination can include physical, chemical, or biological methods. Those that kill or inactivate microbes are labelled sterilization, disinfection, antisepsis, and sanitization.

Microbial fatality contours, which portray the logarithmic decline of living microorganisms after direct exposure to a treatment procedure, are important devices for figuring out the performance of a microbial control approach. The time it takes for a method to generate a 1-log decrease in the microbial population is labelled the decimal reduction worth, or D-value.

To make sure accurate microbial analysis results, it is essential to keep the sample and the test system itself without contamination. Using a microbiological incubator that provides an efficient 140 oC purification cycle, such as the Thermo Scientific Heratherm Incubator, can aid eliminate cross-contamination in between examples and screening tools, therefore ensuring that the results of any microbial examinations stand.

When it involves maintaining your drink steady, Tunnel pasteurizers can do a great deal of job. These machines give both the bottle or can and its components a warm therapy-- which helps extend life span while maintaining those specialty active ingredients craft breweries like a lot.

In a regular Tunnel pasteurizer, the package and fluid are communicated with numerous areas that slowly warm and cool the item. Each spray head provides water at various temperature levels, and the nozzles are positioned to optimize protection with a minimum of thermal anxiety.

The timing and temperature of each spray are based on a beverage-specific number of pasteurization devices (PU) required to kill any microbes in the container. The steady nature of heating additionally decreases carbonation loss in low-carbonated beverages.

Tunnel pasteurizers can be made use of to heat treat a drink also after it has actually been loaded into bottles and canisters. This can assist lengthen shelf security for carbonated beverages without compromising their fizz.

The process works by progressively heating a container with sprays of warm water. The temperature level is increased in stages till it gets to the needed pasteurization system for the drink and then preserved for the defined duration.

Once the desired time and temperature level have actually been accomplished, the beer is cooled down with showers of low-temperature water up until it gets to ambient temperature. This guarantees that all microbes in the beer are killed and it can be safely stored in a sealed container.

Tunnel pasteurizers are designed to make sure that the temperature level is uniformly distributed throughout the whole surface area of the container, assisting attain constant results. This can be tough with various other warmth treatment approaches such as flash pasteurization, however the precise temperature control that Tunnel pasteurizers offer can make all the difference for a brewery's operations.

As beverage makers encounter increasing pressure to lower their carbon impacts, Tunnel pasteurizers are a valuable device for keeping waste to a minimum. The system heats the container to a precise temperature for a set period, getting rid of harmful bacteria without damaging the beverage's physical stability or influencing its flavor account.

As an included advantage, Tunnel pasteurization additionally works wonderful with carbonated beverages-- consisting of the prominent craft makes that numerous beer fans enjoy. It assists to extend their life span while protecting those complex hop keeps in mind that customers like so much.

A business just recently retrofitted their Tunnel pasteurizer to make use of solar energy for heating the fluid, which caused a 35% decrease of water usage. They've likewise carried out a closed-loop waste water treatment plant to even more cut their environmental influence also better. This shows just how essential sustainable methods are, and just how they're crucial to satisfying consumer demand and ecological obligation. Keep tuned for future updates on all of the groundbreakings, job begins, ribbon cuttings and buildouts that are happening around the country!

Tunnel pasteurizers are essential for eliminating wasting microbes and controlling pathogenic germs in drinks like beer, milk, juice and soft drinks. They warm and after that cool down the product to eliminate these germs.

They additionally save power, water and lower co2 exhausts straightening production with sustainability targets. Selecting a passage pasteurization system that's crafted by skilled specialists like PRO makes sure accuracy in the timing and temperature levels used in each phase.

Microbiological Control

The control of bacteria in food and beverages is important to stop perishing, gastrointestinal disorder, and other unfavorable influence on the end product. Microbial contaminations can be brought on by pathogenic (i.e., disease-causing) microorganisms or perishing fungi. just click the up coming document for regulating microbial contamination can include physical, chemical, or biological methods. Those that kill or inactivate microbes are labelled sterilization, disinfection, antisepsis, and sanitization.

Microbial fatality contours, which portray the logarithmic decline of living microorganisms after direct exposure to a treatment procedure, are important devices for figuring out the performance of a microbial control approach. The time it takes for a method to generate a 1-log decrease in the microbial population is labelled the decimal reduction worth, or D-value.

To make sure accurate microbial analysis results, it is essential to keep the sample and the test system itself without contamination. Using a microbiological incubator that provides an efficient 140 oC purification cycle, such as the Thermo Scientific Heratherm Incubator, can aid eliminate cross-contamination in between examples and screening tools, therefore ensuring that the results of any microbial examinations stand.

Stability

When it involves maintaining your drink steady, Tunnel pasteurizers can do a great deal of job. These machines give both the bottle or can and its components a warm therapy-- which helps extend life span while maintaining those specialty active ingredients craft breweries like a lot.

In a regular Tunnel pasteurizer, the package and fluid are communicated with numerous areas that slowly warm and cool the item. Each spray head provides water at various temperature levels, and the nozzles are positioned to optimize protection with a minimum of thermal anxiety.

The timing and temperature of each spray are based on a beverage-specific number of pasteurization devices (PU) required to kill any microbes in the container. The steady nature of heating additionally decreases carbonation loss in low-carbonated beverages.

Safety and security

Tunnel pasteurizers can be made use of to heat treat a drink also after it has actually been loaded into bottles and canisters. This can assist lengthen shelf security for carbonated beverages without compromising their fizz.