SPOILER ALERT!

A Tunnel & Batch Pasteurizer Manufacturer Could Be A Great Investment For Your House Brewing Organization

Content written by-Scott Lewis

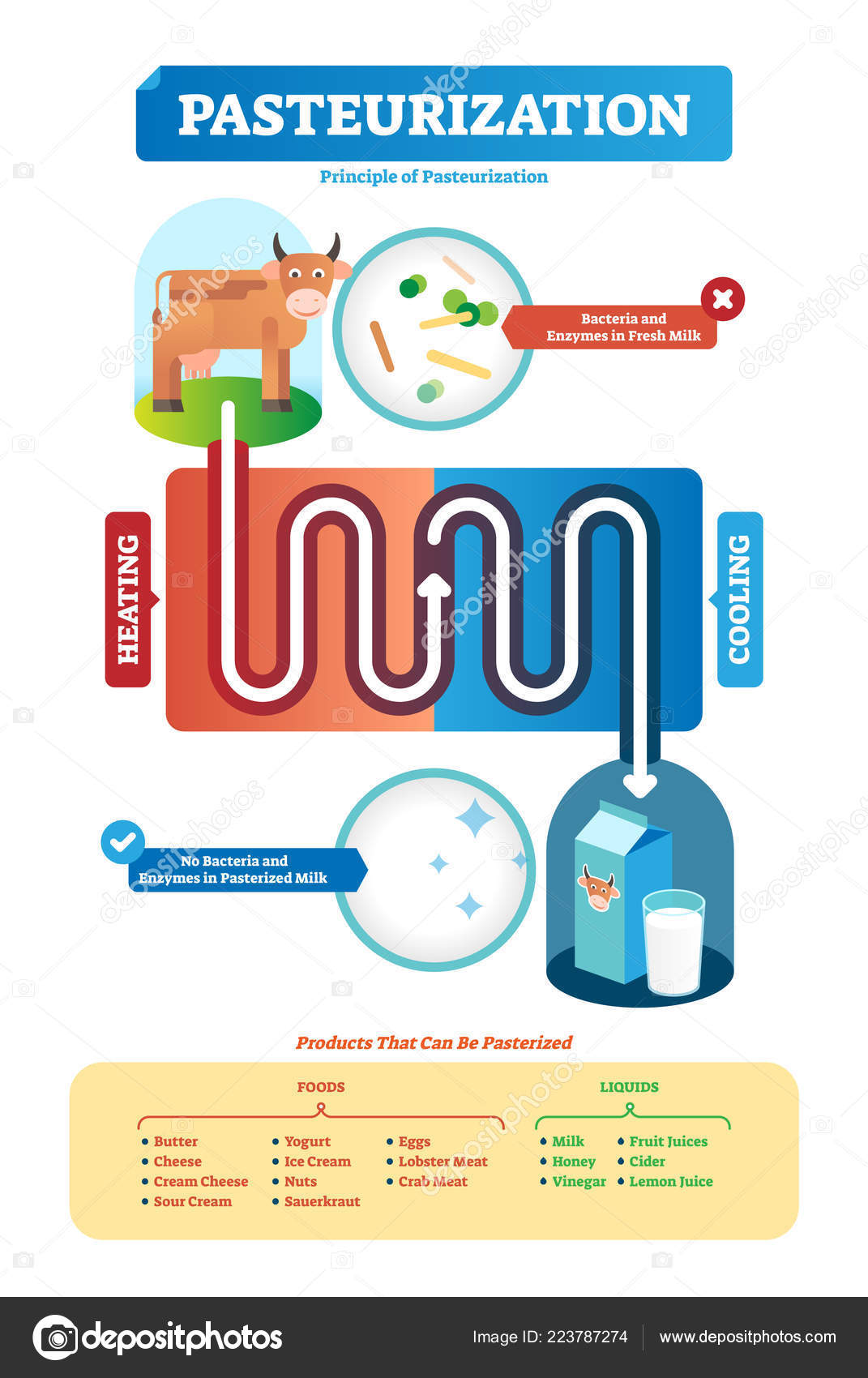

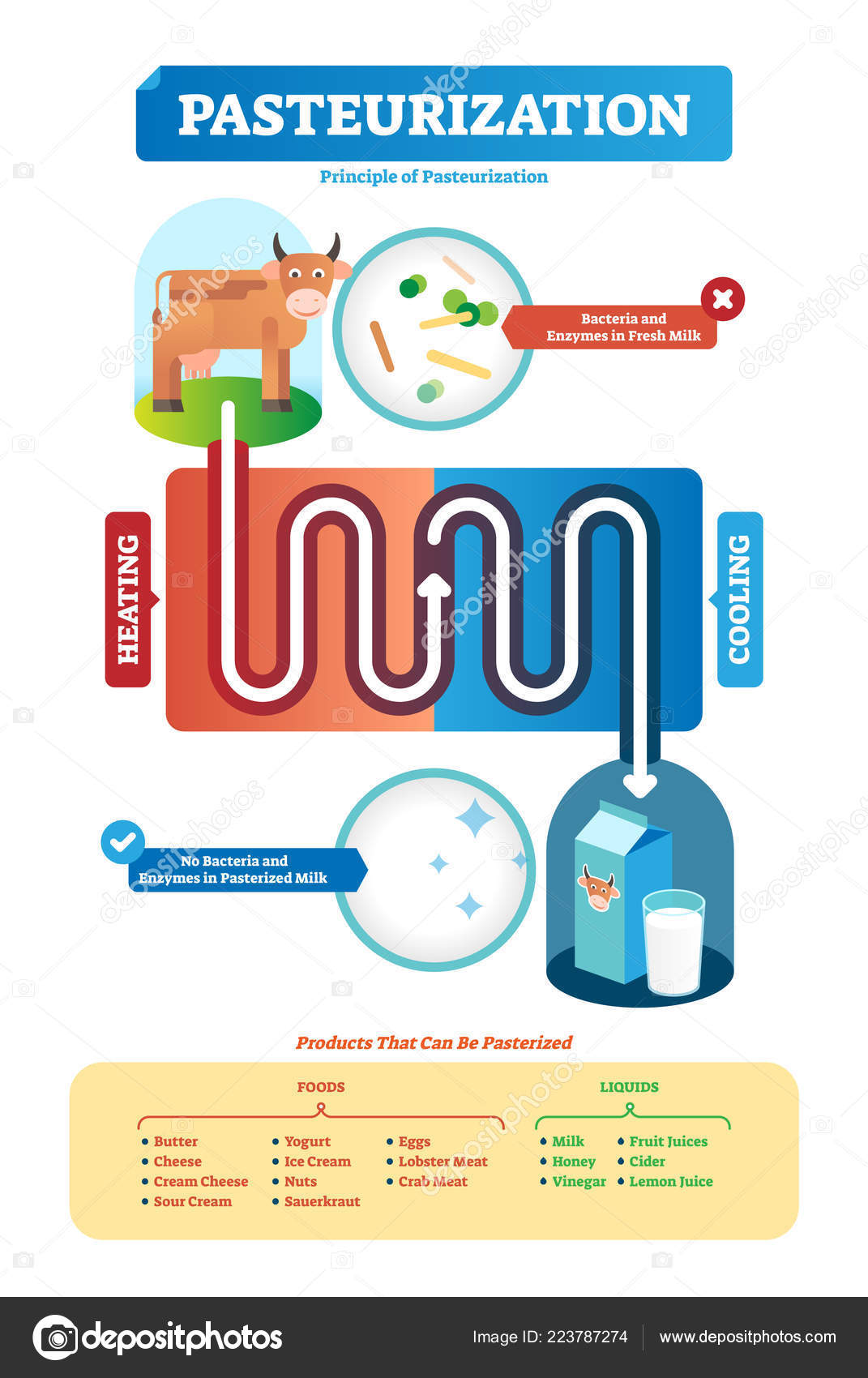

Tunnel and batch pasteurizers are 2 types of pasteurizers. Each is special in their very own right, however both are used to warmth large sets of alcohol or glass of wines at high temperatures. These systems have different methods of creating a pasteurization environment by controlling the quantity of heavy steam, oxygen, as well as other airborne impurities that can be presented into the mix before it goes into the fermenter. Relying on the item as well as desired production price, both may be necessary.

A Tunnel pasteurizer functions by allowing the hot water of the hot water heater to be integrated with the alcohol being produced. The resulting combination is then transferred into the fermenter where the yeast activity happens as well as starts the fermentation process. As the red wine or beer goes through maturation in the fermenter, the staying elements in the remedy begin to break down. These consist of hydrogen sulfide, which is a result of the yeast as well as can differ depending on the particular product.

A lot of passage and set pasteurizers are heating up utilizing lp, oil, or gas in an external system. Nevertheless, some items require an inner heating element using oil or gas to initiate the pasteurization procedure. An inner system is also described as a "baker central heating boiler." A burner head is fitted inside of the internal home heating central heating boiler. The heated air, which passes over the burner head, gives extra oxygen to the beer or red wine. It is these items that are pasteurized.

The primary difference in between a tunnel pasteurizer and also a batch pasteurizer is the manner in which they heat up the item. A tunnel pasteurizer heats the product directly making use of radiation or heat. It is effective for high quantity, shallow distillation applications. Set pasteurizers are more efficient than their equivalents since they can heat up as well as flow a big quantity of fluid at once.

Many items make use of a warm exchanger within the tank. Warmth exchangers are incredibly efficient at rapidly heating an incredibly hot fluid, such as as needed distilled water. Due to the fact that they are so reliable, they can frequently be made use of together with a steam boiler, which is a much bigger system that additionally includes a warmth exchanger container. One sort of this type of pasteurizer is called a "cobra die" and also it is basically a cylinder full of a highly heated mineral solution. When the temperature level climbs inside the cyndrical tube, the minerals start to vaporize and become pure water.

Passage & Batch Pasteurizers can be used for a variety of applications. Some sterilizing techniques use a low temperature and high pressure heavy steam stream to rapidly heat up a service. additional reading of systems are generally made use of in the manufacturing of alcoholic beverages. Others are made use of to speed up the aging process of beer by encouraging the growth of helpful microorganisms.

There is a lot of clinical study being conducted on the effectiveness of passage & set pasteurizers as relates to the production of alcohols. Along with their benefits to the home brew enthusiast, they have actually shown substantial pledge in being utilized in the food as well as pharmaceutical industries. Pasteurization is a process that has remained in location because the 1800's in order to protect against dangerous microorganisms and also infections from taking hold in the products that we consume. This process is generally made use of in order to reduce or remove a variety of pathogenic components that might intimidate the general public's health and wellness. mouse click the up coming internet site has actually also shown to be extremely effective in lowering the germs and also fungus that are accountable for producing numerous usual foods items.

The Pasteurizer Central heating boiler Design is essential to the top quality of the item as well as to the overall success of the product. This is since there are numerous factors that can potentially cause inadequate performance in the pasteurizer, such as an improperly sized nozzle, a lack of anxiety, a low boiling point, or an ineffective amount of warmth related to the pasteurizer. The design of a properly sized tunnel & set pasteurizer makes it feasible to get every one of the essential heat as well as frustration to be applied without needing to apply more than essential. Properly developed and sized items are extremely reliable in their own right, however can likewise be of benefit to the food and pharmaceutical industries when made use of as mixers with other sanitizers and also anti-bacterials.

Tunnel and batch pasteurizers are 2 types of pasteurizers. Each is special in their very own right, however both are used to warmth large sets of alcohol or glass of wines at high temperatures. These systems have different methods of creating a pasteurization environment by controlling the quantity of heavy steam, oxygen, as well as other airborne impurities that can be presented into the mix before it goes into the fermenter. Relying on the item as well as desired production price, both may be necessary.

A Tunnel pasteurizer functions by allowing the hot water of the hot water heater to be integrated with the alcohol being produced. The resulting combination is then transferred into the fermenter where the yeast activity happens as well as starts the fermentation process. As the red wine or beer goes through maturation in the fermenter, the staying elements in the remedy begin to break down. These consist of hydrogen sulfide, which is a result of the yeast as well as can differ depending on the particular product.

A lot of passage and set pasteurizers are heating up utilizing lp, oil, or gas in an external system. Nevertheless, some items require an inner heating element using oil or gas to initiate the pasteurization procedure. An inner system is also described as a "baker central heating boiler." A burner head is fitted inside of the internal home heating central heating boiler. The heated air, which passes over the burner head, gives extra oxygen to the beer or red wine. It is these items that are pasteurized.

The primary difference in between a tunnel pasteurizer and also a batch pasteurizer is the manner in which they heat up the item. A tunnel pasteurizer heats the product directly making use of radiation or heat. It is effective for high quantity, shallow distillation applications. Set pasteurizers are more efficient than their equivalents since they can heat up as well as flow a big quantity of fluid at once.

Many items make use of a warm exchanger within the tank. Warmth exchangers are incredibly efficient at rapidly heating an incredibly hot fluid, such as as needed distilled water. Due to the fact that they are so reliable, they can frequently be made use of together with a steam boiler, which is a much bigger system that additionally includes a warmth exchanger container. One sort of this type of pasteurizer is called a "cobra die" and also it is basically a cylinder full of a highly heated mineral solution. When the temperature level climbs inside the cyndrical tube, the minerals start to vaporize and become pure water.

Passage & Batch Pasteurizers can be used for a variety of applications. Some sterilizing techniques use a low temperature and high pressure heavy steam stream to rapidly heat up a service. additional reading of systems are generally made use of in the manufacturing of alcoholic beverages. Others are made use of to speed up the aging process of beer by encouraging the growth of helpful microorganisms.

There is a lot of clinical study being conducted on the effectiveness of passage & set pasteurizers as relates to the production of alcohols. Along with their benefits to the home brew enthusiast, they have actually shown substantial pledge in being utilized in the food as well as pharmaceutical industries. Pasteurization is a process that has remained in location because the 1800's in order to protect against dangerous microorganisms and also infections from taking hold in the products that we consume. This process is generally made use of in order to reduce or remove a variety of pathogenic components that might intimidate the general public's health and wellness. mouse click the up coming internet site has actually also shown to be extremely effective in lowering the germs and also fungus that are accountable for producing numerous usual foods items.

The Pasteurizer Central heating boiler Design is essential to the top quality of the item as well as to the overall success of the product. This is since there are numerous factors that can potentially cause inadequate performance in the pasteurizer, such as an improperly sized nozzle, a lack of anxiety, a low boiling point, or an ineffective amount of warmth related to the pasteurizer. The design of a properly sized tunnel & set pasteurizer makes it feasible to get every one of the essential heat as well as frustration to be applied without needing to apply more than essential. Properly developed and sized items are extremely reliable in their own right, however can likewise be of benefit to the food and pharmaceutical industries when made use of as mixers with other sanitizers and also anti-bacterials.